1 .No rise in temperature: the temperature will not increase as the materials are pulverized under the working conditions of pneumatic expansion and the temperature in the milling cavity is kept normal. 2. No contamination: the whole process is contamination-free as the materials are moved by the airflow and ground through the collision and impact among themselves without involving the media. Fully self-grinding, So The device is durable and the purity of products is high in contrast.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process. 3. Endurance: Applied to materials with mohs' hardness below grade 9, since the milling effect only involves the impact and collision among the grains rather than the collision with the wall. especially for the materials with high hardness, high purity and high added value. 4. Weighing control system, high precision, optional, high product stability. Optional explosion-proof design, can also be upgraded to nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials. 5.Available particle size D50:1-25μm.Good particle shape, narrow particle size distribution. The world's leading high-precision classifier rotor with line speeds up to 80m/s, ensuring high precision for product requirements.Speed of wheel is controlled by converter, particle size can be adjusted freely. The classifying wheel separates the material automatically with airflow, no coarse particles.Ultrafine powder product is stable and reliable. 6.Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature. 7.High energy utilization rate, promote material flow, improve powder screening efficiency. 8.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final. 9.PLC control system, easy operation. 10.The motor can be connected with belt to increase the speed and break through the problem of high-speed motors without the well-known motor brand. Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

1 .No rise in temperature: the temperature will not increase as the materials are pulverized under the working conditions of pneumatic expansion and the temperature in the milling cavity is kept normal. 2. No contamination: the whole process is contamination-free as the materials are moved by the airflow and ground through the collision and impact among themselves without involving the media. Fully self-grinding, So The device is durable and the purity of products is high in contrast.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process. 3. Endurance: Applied to materials with mohs' hardness below grade 9, since the milling effect only involves the impact and collision among the grains rather than the collision with the wall. especially for the materials with high hardness, high purity and high added value. 4. Weighing control system, high precision, optional, high product stability. Optional explosion-proof design, can also be upgraded to nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials. 5.Available particle size D50:1-25μm.Good particle shape, narrow particle size distribution. The world's leading high-precision classifier rotor with line speeds up to 80m/s, ensuring high precision for product requirements.Speed of wheel is controlled by converter, particle size can be adjusted freely. The classifying wheel separates the material automatically with airflow, no coarse particles.Ultrafine powder product is stable and reliable. 6.Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature. 7.High energy utilization rate, promote material flow, improve powder screening efficiency. 8.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final. 9.PLC control system, easy operation. 10.The motor can be connected with belt to increase the speed and break through the problem of high-speed motors without the well-known motor brand. Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.Product Description

Product test procedure introduction-adjust products’ fineness according to customers’ requirement

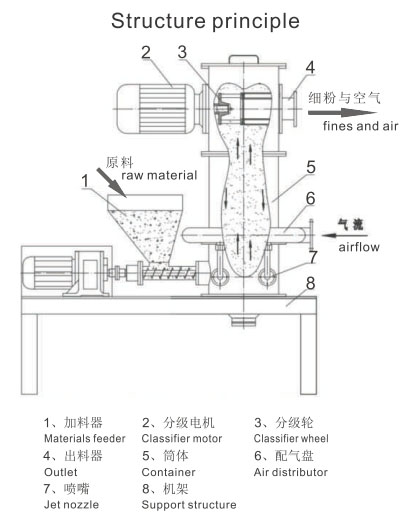

The Fluidized-bed Jet mill is actually such a device that using the high speed air flow to perform the dry-type superfine pulverizing. Driven by compressed air, raw material is accelerated to the crossing of four nozzles to be impacted and grinded by upward flowing air to the grinding zone, influenced by centrifugal force and air flow, powder up to grading wheel will be separated and collected(the bigger the particles is , the stronger the centrifugal force is; The fine particles that meet size requirement will enter the grading wheel and flow into the cyclone separator and get collected by the collector. );other powder swirls back to milling chamber for further milling processing. Notes: Compressed air consumption from 2 m3/min up to 40 m3/min. Production capacity depend on specific characters of your material, and can be tested in our test stations. Data of production capacity and product fineness in this sheet are just for your reference. Different materials have different characteristics, and then one model of jet mill will give different production performance for different material. Please contact me for tailored technical proposal or trials with your material.Operational Principle

QDF fluidized bed pneumatic mill can crush the following special material in addition to the common materials. High hardness material: tungsten carbide, carborundum, aluminum oxide, silicon oxide, silicon nitride, etc. High purity material: super-conducting material, special ceramics, etc Heat sensitive material: plastics, medicine, toner, organic material, etc. Our products mainly used in below industries.Now We have had a mature market in Agricultural chemical field. But we never stop our pursuit for excellence and apt to learn customers so that we could provide them better service and solutionsContact Us

The flow chart is standard milling processing,and can be adjusted for customers. Our project team works based on a substantial test database with over 5000 test reports of over 1000 various material from mineral industries, chemical industries, food and agriculture industries, pharma industries etc.

The flow chart is standard milling processing,and can be adjusted for customers. Our project team works based on a substantial test database with over 5000 test reports of over 1000 various material from mineral industries, chemical industries, food and agriculture industries, pharma industries etc.

Flow chart of Fluidized-bed Jet Mill

Crushing Example

We are manufacturer for powder processing machines. More important, we provide tailored design of machine, of engineering, of control system to meet our clients' production requirements. We are a project supplier. We provide solution for powder processing.

We are manufacturer for powder processing machines. More important, we provide tailored design of machine, of engineering, of control system to meet our clients' production requirements. We are a project supplier. We provide solution for powder processing.Features

Step 2 Start up PLC program.Through control classifer wheel’s frequency ,control products’fineness. Step 1 Directly start up air source system machines.

Step 1 Directly start up air source system machines. Step 3 Adding raw material to loading hopper or feeding device.For lab QDF-120 machine,We can adopt air suction way through negative pressure to feed material;for production machines ,batch feed or bag feed is avaiable to satisfy different requirement.

Step 3 Adding raw material to loading hopper or feeding device.For lab QDF-120 machine,We can adopt air suction way through negative pressure to feed material;for production machines ,batch feed or bag feed is avaiable to satisfy different requirement.

Step 4 Collecting finished products according to customers’ ways,You can directly collect finished products by buckets ,or connect to packing machine.

Step 4 Collecting finished products according to customers’ ways,You can directly collect finished products by buckets ,or connect to packing machine.

Partial Application Examples

PLC Control system The system adopts intelligent touch screen control, easy operation and accurate control.